|

2007 Racing Year

MINI-WEDGE RACING ASSOCIATION

A sanctioned racing body for children 7-14 years of age

Contact for MWRA:

Troy Kimbrew

304-265-6208 home

304-290-8750 cell

MINI-WEDGE RACING ASSOCIATION RULES AND REGULATIONS

Rules may be changed/amended by MWRA when deemed necessary.

MINI WEDGE RACING ASSOCIATION

MISSION

To provide the safest racing program possible designed to teach young drivers the skill, sportsmanship, and fairplay needed

to compete on and off the track.

VISION

The MWRA will be known throughout the racing world as the standard in safety, quality, and value.

No other organization will pose a serious threat to our continued success.

MWRA will be a great experience for both parent and child.

Opportunities for continuous education and growth will foster personal and career growth.

Our efforts will be recognized by others who view us as a benchmark for safety and fairness.

VALUES

We must strive to provide a fun and safe environment for every person.

We do believe all of our members desire to excel in their life.

We must treat each other fairly with respect, plus offer encouragement and appreciation as we work together towards the

same goals.

To promote families spending good, quality time together, at or away from the racetrack.

2007 Rules and Regulations

Car Section 1

Engine Section 2

Race Rules Section 3

Driver Personal Safety

Section 4

Tech Inspection Section 5

Body Drawings/Specs

Section 6

The MWRA encourages a fun, family atmosphere. Times may arise that are stressful and upsetting to both parents and the

driver. When addressing these issues, please speak in a manner that is respectful not only to the driver, but to others that

are within hearing distance.

The following are rules for the Mini Wedges. Cars can be built from MWRA approved chassis (Falcon, Miller, Boss, Rocket,

etc.) or of new construction, which must be inspected and approved by a MWRA official.

Membership in the MWRA shall be $25.00 per year. Membership is required at ALL MWRA tracks. Membership applications can

be obtained by contacting Missey and Troy Kimbrew at 304-265-6208 or requested by e-mail at kimbrew93@aol.com.

Section 1- CAR

Section 1

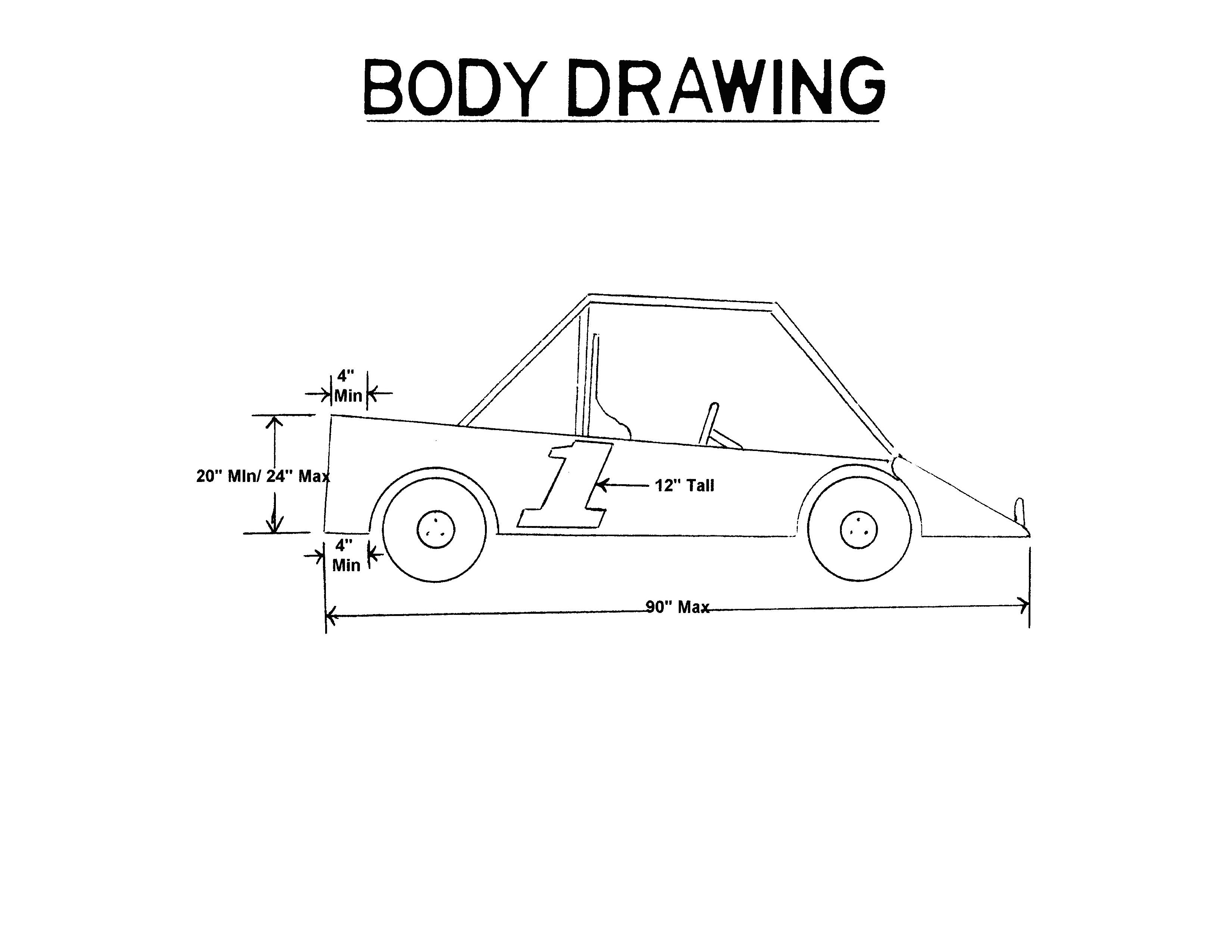

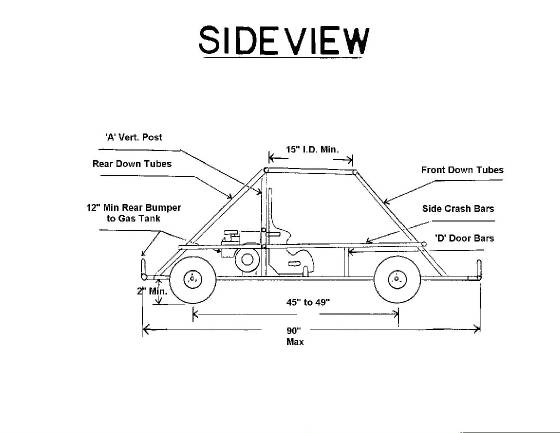

A: Wheelbase 45 to 49"

Maximum Width (outside tires) 48"

Minimum ground clearance 2"

No Roofs

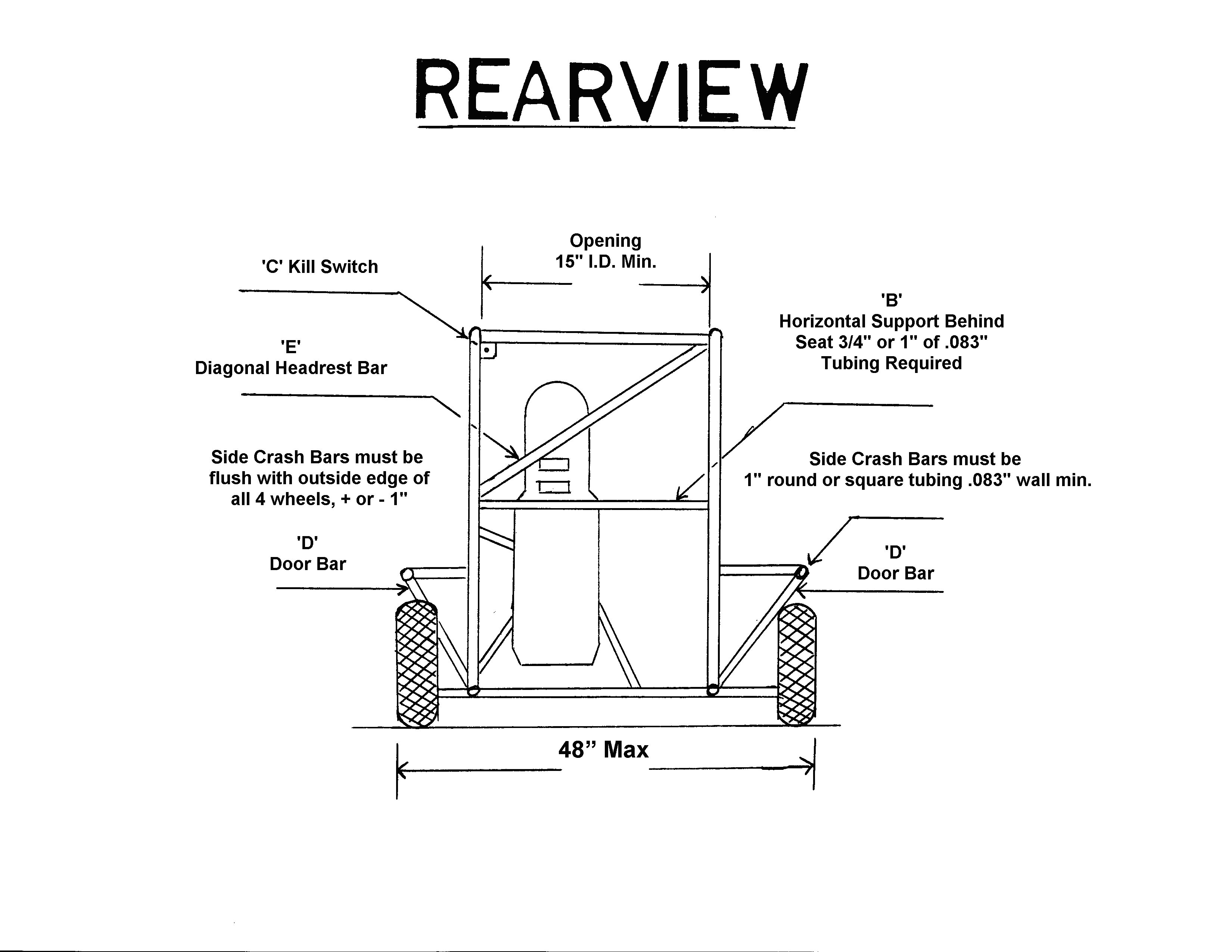

B: All cars must be constructed of steel tubing with a complete 6-point roll cage including adequate side protection.

Cage must be a minimum of .083" x 1" steel tubing welded to the frame.

C: Engine must be behind the driver's seat.

D: Floor pan required of steel or minimum .063" aluminum securely bolted (no pop rivets) to the frame and must fully

cover from the seat front to past the foot pedals.

E: All cars must have a body with fully enclosed wheels and tires. No open wheel cars permitted. There must be at least

4" of body behind the rear wheels. There must be at least a 4" wide rear deck panel behind the motor compartment

opening. There will be no covered or enclosed motors. All motors will remain completely visible at all times (see body drawing).

Interior driver cockpit must be enclosed. No exceptions to this rule.

F: You have the option to run Knobbie tires (sizes 4.10 x 3.50-4, 4.10 x 3.50-5, or 4.10 x 3.50-6) or Slicks. Approved

Slicks are Burris (sizes 5.10/11.0 x 6 ss22 compound) or Hoosiers (size 33.0/4.5 x 6 D 20 compound only. Hoosier part # 15300).

No grooving or slicing of the tires.

G: No suspension allowed, no springs, shocks, rubbers or torsion bars of any type permitted.

H: Rear deck height maximum 24" high from ground minimum 20" high from ground plus or minus 1".

I: Body must be constructed of .040" aluminum. Plastic may be used for nose and trim.

J: Any chassis bars above 6" from ground cannot have more than 2" of protruding ends. This includes body brackets

and supports. Measurement will be made from the closest welded joint.

K: Side crash bars must be flush with outside of front and rear wheels, plus or minus 1/2".

L: Side crash bars must run lengthwise from at least center of the front wheel hub to center of the rear wheel hub.

M: Side crash bars must be at least 1" round or square tubing with .083" minimum wall thickness.

N: Side crash bars must be welded to the main frame in no less than 4 places with at least 3/4" x .083" wall

tubing. Dash bar must be welded to the front down tubes and the side crash bars. No floating bars allowed.

O: At least one vertical door bar must be welded on each side of driver running from the main rail to side crash bars

for driver protection. Must be 3/4" or larger .083" wall (see rear, side view, drawing "D").

P: Front and rear bumpers must be at least 3/4" x .083" wall tubing.

Q: Bottom of control pedals must be connected to the frame behind the front down tubes or to the floor pan.

R: Front and rear down tubes are mandatory.

S: All tubing on main roll cage including side crash bars and bumpers must be .083" wall minimum.

T: Vertical support posts (see side view, drawing "A") must run from main frame rail to top of roll cage, be

welded on both ends and be constructed of at least 1" round or square tubing with at least .083" wall. Must be one

right and one left positioned near drivers shoulder and run near parallel with the back of the seat.

U: Seat mounts (4) required and must be constructed with no less than 3/4" x .083" wall tubing or 3/16"

thick flat steel material and all mounts must be welded to the main frame. NO clamp on mounts permitted.

V: All cars must have a horizontal cross bar behind the seat, positioned about half way between the bottom frame rails

and the top of the roll cage constructed of no less than 3/4" x .083" wall tubing and welded to the vertical support

posts (see "B" rear view drawing).

W: All cars must have a minimum 12" number on both sides of the car. If your number is too small or not easy to read,

you may not be scored.

X: Aluminum racing style, high back, padded seats are mandatory on all mini-wedge cars.

Y: Throttle pedal or control rod must have a return spring along with a return spring on the carburetor throttle linkage.

Z: Brakes must be in proper adjustment and in safe working order.

AA: Two (2) kill switches must be on the car and both must shut down the motor separately. One (1) must be located in

the cockpit and within driver's reach with arm restraints in use.

One (1) must be located at the top left rear corner of the roll cage (see rear view drawing "C").

BB: No kill buttons. All kill switches must be an ON/OFF type switch.

CC: All cars must have a metal/aluminum chain guard.

DD: All cars must weigh a minimum of 315 pounds after the race with the driver and safety equipment. Cars may be weighed

at any time. Each track may use its own method of weighing the car.

EE: Any weight added to the car MUST be bolted or welded to the frame. Approved weight clamps may be used. NO hose clamps,

duct tape, zip ties, bungee cords, etc. All weight must be painted white with name and cart number on it. If weight is lost

during a race/heat you will be disqualified.

FF: All framework, except upper roll cage, MUST be within the bodylines of the car. NO exposed side crash or side nerf

bars.

GG: You must have snap rings installed on the ends of the rear axle at all times.

HH: All cars must have a 5-point harness system securely fastened to the main frame of the chassis. This harness must

have an SFI rated patch and a manufacturer's date tag and must be no more than 2 years old according to the manufacturer's

date tag.

II: All cars must have 2 triangle type side window nets attached to the roll bar. These nets are similar to those used

in sprint cars, midgets and 1/4 midgets.

JJ: All cars must run four (4) windshield bars running VERTICALLY in front of the driver. These bars must be made of no

less than 5/16" solid rod and cover at least 1/2 of the total open area measured from the front top cross to the deck.

Bars must be welded or bolted to the front down tubes. NO hose clamps or zip ties.

KK: A bar made of 3/4" or larger must be installed behind the headrest of the driver's seat running diagonally from

the top of the roll cage to approximately midway down to the horizontal support on the opposite side. It may run either direction,

but right hand top corner to bottom left is recommended (see rear view drawing "E").

LL: 12" minimum distance from the rear bumper to the gas tank of motor (see side view drawing).

MM: One inch plastic or aluminum flat strap may be used to support rear quarter panel from bottom of frame.

NN: No heim joints, slip joints, torsion bars, spring, etc. shall be used in construction of the main frame.

OO: Front and rear down tubes must be 1" round or square tubing of .083" wall thickness. Rear down tubes must

be welded to vertical side post at least 18" up from the top of the main frame rails and run down toward the rear of

the car to connect to the main frame rail behind the rear axle.

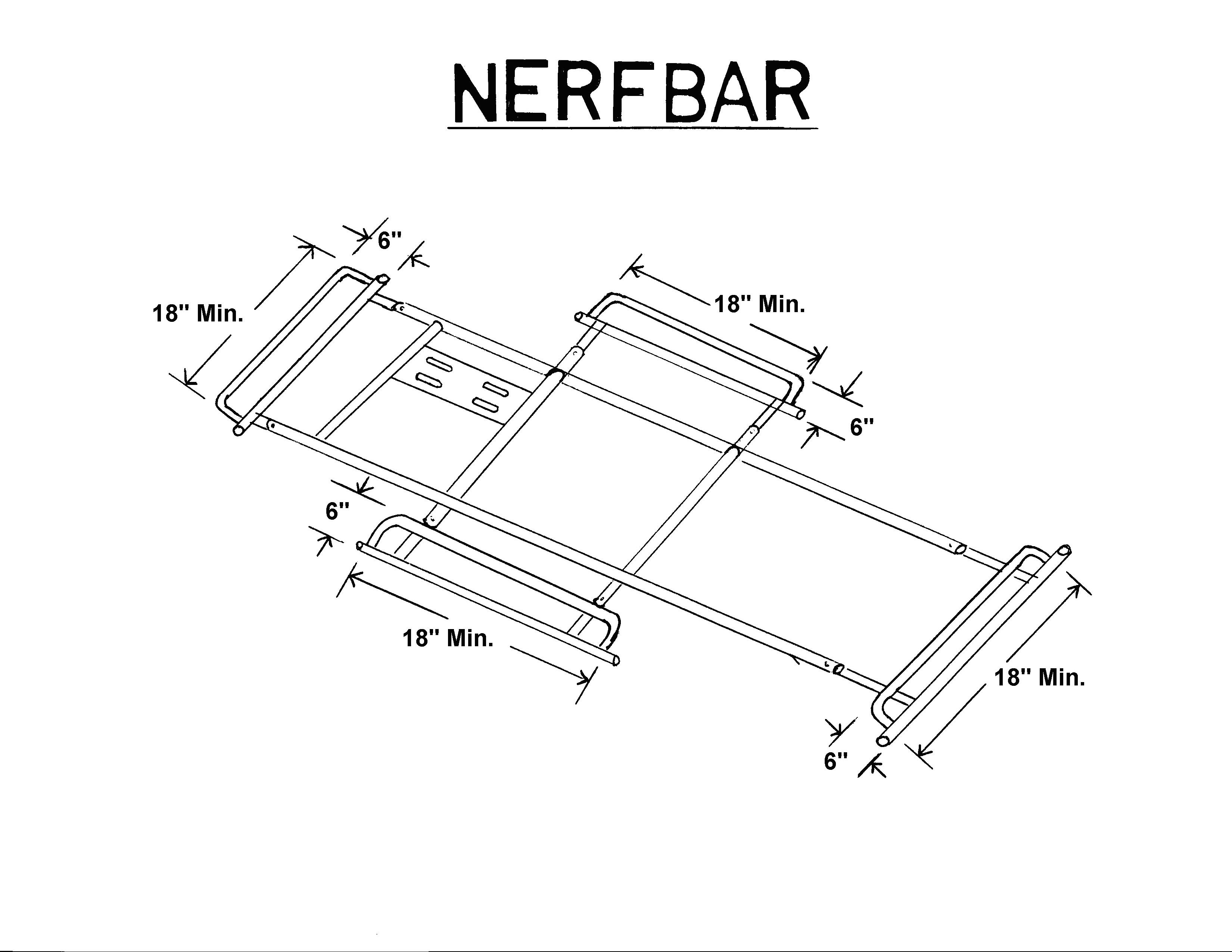

PP: All cars must run front, rear, and side nerf bars (see Nerf Bar drawing). Nerf bars must be made of at least 3/4"

round tubing either bolted or welded to the main frame. All nerf bars must be at least 6" tall and 18" long.

QQ: Side nerf bars must run flush with the side crash bars.

RR: Front and rear nerf bars must be welded to the bumpers on the outermost edge and stand 90 degrees to the ground, they

cannot lean out or back (see Nerf Bar drawing).

Section 2-Engine

Section 2

A: Power must be transmitted by a centrifugal type clutch. No direct drive or push start cars allowed. No variable drive

systems. No belt drives.

B: Engines must be 5 HP four stroke Briggs & Stratton ONLY.

All parts must be Briggs & Stratton factory production parts unless otherwise specified in this manual. No machining

or alteration of parts is permitted unless specifically noted. All parts are subject to be compared to a known stock Briggs

& Stratton part. No reading between the lines. If it is not in the rules, it must remain stock. UNLESS OTHERWISE STATED,

ENGINE WILL BE TECHED AS RACED.

C: All motors must run MWRA Spec header ONLY.

D: No other exhaust will be legal. Header must be stamped MWRA and can only be purchased from Dave Poske's Performance

Parts, Parkersburg, WV. Phone 1-800-430-7723. Part # MWRA-EX.

E: No use of alcohol or fuel additives. Fuel can be checked at any time with a fuel hydrometer. It is the owner's option

to check the fuel before the race. Fuel rating may vary from week to week. If you don't know where your fuel is, test it!

This is your responsibility. If fuel is tested after racing and deemed "illegal" you will be disqualified and suspended

according to Section 5L. Fuel reading must be no lower than -30.

F: Governor may be removed or unhooked.

G: No Raptor II or Raptor III Briggs & Stratton Motors. However, Raptor II & III blocks, crankshafts, rods, and

cams may be used. If a Raptor or old style crankshaft is used, the long end where the starter clutch fits on must be removed

to allow the use of the newer cup style starter.

H: No machine work can be done to the motor with the exception of making factory parts to be within specs as noted.

I: Boring and honing of the cylinder can be done to save the motor. However, the over bore size cannot exceed .030"

(stock bore size 2.5625" over bore size 2.5925"). Only Briggs & Stratton pistons can be used and must have size

stamped on top.

J: Cylinder head measurements are as follows:

The flat area above the piston shall not be less than 0.011".

The area of the spark plug shall not be less than 0.408".

The area above the valves shall not be less than 0.300".

The above measurements are an absolute minimum, therefore there should be little additional material left for a "cushion"

amount (to allow for gasket cleaning and carbon buildup, etc.)

K: Camshaft profile shall be as follows:

The following readings are taken with 0 valve lash and with degree wheel set at 0 degrees at TDC of the compression stroke.

Exhaust Intake

Lift Degrees Lift Degrees

.020" 51 BBDC to 46 BBDC .020" 18 BTDC to 13 TDC

.050" 38 BBDC to 33 BBDC .050" 7 BTDC to 0 TDC

.100" 21 BBDC to 16 BBDC .100" 10 ATDC to 17 ATDC

.150" 2 BBDC to 3 ABDC .150" 29 ATDC to 36 ATDC

.200" 21 ABDC to 31 ABDC .200" 55 ATDC to 64 ATDC

Max Max lift is .233"; Max Max lift is .233"

.200" 76 BTDC to 65 BTDC .200" 43 BBDC to 33 BBDC

.150" 48 BTDC to 40 BTDC .150" 13 BBDC to 6 BBDC

.100" 28 BTDC to 21 BTDC .100" 6 ABDC to 13 ABDC

.050" 10 BTDC to 4 BTDC .050" 23 ABDC to 31 ABDC

.020" 2 ATDC to 7ATDC .020" 40 ABDC TO 45 ABDC

Note: All cam profile readings must be taken with zero (0) valve lash. When checking cam profile, rotate engine in the

normal running direction only. Valves should have no running clearance when checked.

Maximum camshaft base circle is 0.760"

Minimum camshaft base circle is 0.735"

L: Breather tube can be removed from the carburetor, the hole in the carb plugged, and then rerouted toward the ground.

M: The only carburetor allowed will be the fixed jet type with 2 mounting holes for the air cleaner. No modifications

to the carb may be done except to change the fixed idle jet to a screw type (no machining allowed). The throttle stop may

be filed to allow for max. opening.

N: An adapter plate can be purchased which will allow the use of the older style blocks, which only have a 2-bolt pattern.

The only adapter that will be allowed will be stamped MWRA-ADPT and shall be available only from Robert Martin in Moundsville,

WV. Phone 304-843-1598, evenings.

O: You may have a crankshaft machined from 1" dia. down to 3/4" dia. to allow the clutch to fit.

P: No Raptor style recoil starters allowed. No square type starter drive nuts allowed. No long crankshafts allowed. No

removable starters allowed.

Q: No pop up pistons or altered strokes allowed.

R: No high performance camshafts allowed. Cam lobe surface cannot be altered in any way. Lobe surface subject to visual

tech. Reworked cams are illegal.

S: No twisted camshafts allowed.

T: No offset keys. No filing or milling of the keys.

U: No honing, sanding, sizing, or tampering with the carburetor. Maximum carburetor bore size shall be .758" and

shall be checked with a .758" dia. "NO GO" gauge. Minimum bore size shall be .748" in dia.

V:Only normal valve work can be done.

W: No larger or smaller valves will be permitted.

X: No tampering with the header. The header can have a fitting welded on to allow for an exhaust temperature sensor. The

header can have a "Jet Hot" coating.

Y: May sleeve block-deck top block flat.

Z: Max pop up of the piston shall be .005". Different length rods are available to remedy this condition should it

happen.

AA: Max lift on the valves shall be .225 with valve lash.

BB: No "Trick" throttle shafts.

CC: Stock valve springs only.

DD: All carburetors must have a working choke.

EE: You may run double gaskets on the tank and the inside cover.

FF: Stock head gaskets only. No copper gaskets allowed. No sealer on gaskets. Tech inspector is not responsible for bringing

head gaskets when cart gets inspected.

GG: You may file the throttle stop for maximum opening of the throttle.

HH: You may run an after market dipper or the Briggs & Stratton rod with the built on dipper. NO billet rods shall

be allowed.

II: You may have a bronze bushing installed in the crankcase or drill an extra oil hole to help the motor last.

JJ: No degreeing the cam. This WILL be checked.

KK: No Raptor III pistons allowed.

LL: Cars must be recoil type start and it shall be permanently attached to the motor.

MM: Must have a stock key in the flywheel and NO filing of the key.

NN: No removable or changeable jet carburetors will be permitted. No matter if they have a working choke or not.

OO: The only 2 air cleaners that shall be allowed will be the plastic top steel bottom factory Briggs & Stratton Part

# 692321 along with the factory Briggs & Stratton filter or a K&N filter #G-80, a K&N pre-filter # G1262. The

above listed air filter shall be mounted with an adapter available from American Power Sports #AP2236. Phone 800-262-0555.

Adapter #AP2236 is recommended but may use a generic type air filter with the same diameter and height as the K&N filter

#G-80. (Outerwear optional.) The foam filter must be in place.

PP: Port surfaces are a non-visual tech item. Intake port is subject to a .880" dia. "NO GO" gauge check.

NO ADDITION OF MATERIAL ALLOWED. Block MAY NOT be machined on the intake or exhaust port surfaces. NO GRINDING is allowed

on the underside of the valve seat. NO HOLES in ports allowed. Allen bolts may be utilized to attach the carburetor and/or

exhaust attachment. If port is pin pinched, it may not be done in a manner to prevent entry of a "NO GO" gauge into

the port area.

QQ: No Raptor type recoil starters. No square type starter driver nut. This means no long crankshafts permitted.

Section 3-Race Rules

Section 3

A: All drivers must be accompanied by a PARENT or LEGAL GUARDIAN. Unless you are appointed his/her legal guardian, by

law, you cannot sign a release form for them. Therefore, they cannot race. Any exception to this rule cannot be made by an

MWRA official and must be brought before the track's management or track's insurance carrier for a decision.

B: All cars will be lined up according to their pill draw. Failure to draw a pill before the line-up is turned into the

track officials will result in the driver starting at the tail of the heat.

C: You need to know when you will be racing. Allow plenty of time to prepare the driver. (buckling in, suiting up, etc.)

D: MWRA officials are not responsible for each driver and ensuring that they are prepared to race. Be prepared to race

at a moment's notice! All cars are to be kept in the MWRA pit area. This allows all carts to be teched, weighed, etc.

E: Track officials in the scoring tower will make all scoring and judgment calls. Their decisions are FINAL.

F: Arguing about scoring or judgment calls will not be tolerated. Confrontations/arguments with MWRA Officials, track

officials or another parent can result in a minimal suspension of two weeks from all MWRA sanctioned tracks.

G: The scoring tower is off limits to drivers and anyone who is not a Track Staff member.

H: Any parent, driver, or member of any team involved in any type of confrontation with anyone at the track will result

in a suspension of the driver for at least two weeks from ALL MWRA events at any track.

I: Age limit is 7 years through 14 years of age. You MUST provide a copy of your birth certificate before your first race

at registration. Age is determined at the beginning of the racing season. (If child is 14 at the beginning of the season

and turns 15 during the season, he/she may complete the racing season.)

J: If a motor change is necessary after the heat race, you must "tag the tail" in the feature race.

K: In cases where a cart is being driven by anyone other than the registered driver of that cart (substitute driver) points

are given to the substitute driver. The substitute driver's number must be placed on the cart the he/she is driving.

Section 4-Driver Personal Safety

Section 4

A: All drivers must wear an approved SFI-1 certified or SF13-2A/1 fire suit. SFI certification patch shall be required

on fire suit.

B: A full face Snell 95 rated helmet will be mandatory at all tracks and at all MWRA events. No motocross type helmets

with goggles and mouth guard will be allowed.

C: All drivers must wear a neck brace.

D: All drivers must wear arm restraints. Arm restraints are to be worn between the elbow and wrist area.

E: MWRA strongly recommends the use of fire resistant underwear.

F: All drivers must wear a closed toe shoe. No sandals, flip-flops, etc. A fire resistant racing shoe is strongly recommended.

G: Fireproof gloves are mandatory at all MWRA events.

H: To ensure the safety of all drivers, drivers that have injuries that would affect their ability to drive (broken bones,

casts, medications that affect driving ability, etc) will not be permitted to participate in MWRA races/events until a written

medical release is received from the driver's physician.

Section 5-Tech Inspection

Section 5

A: MWRA officials will visually inspect cars.

B: MWRA Tech inspectors may do a motor "tear down" on any cart he /she chooses, at any MWRA event. MWRA officials

will be trained to perform a complete motor tech. Inspectors are not responsible for reassembling engines after inspection.

C: The Tech inspector may tear a motor down as far as he/she believes necessary.

D: If the inspector rules that your motor or part of your motor is illegal, you will be disqualified. The inspector's

decision is final.

E: If you have any question about your motor being legal, YOU need to have it checked. It is your responsibility to make

sure that your motor is legal. A brand new (out of the box) motor does not make it legal. There are variances in the manufacturing

processes.

F: If an official decides that your car or part of your cart is illegal or unsafe, you will be asked to fix it prior to

racing it. Any MINOR infraction you are asked to fix MUST be taken care before your next MWRA race.

G: Any participant, car and/or motor may be inspected anytime, at any track, regardless of their race results.

H: If a Tech inspector deems that any part of your car or motor is illegal, you will be disqualified.

I: If any participant, car, motor, or personal safety equipment is found to be improper, unsafe, or illegal, you will

be disqualified.

J: All tech procedures are done using MWRA tech gauges, not the racer's gauges.

K: Minor infractions such as no gloves, no neck brace, no chain guard, body work infraction, loss of ballast, rough driving,

jumping the start, arguing with others, failure to slow down after checkered flag, etc., could result in a loss of track points

and a 2 week suspension.

L: Major infractions are considered as any illegal act committed on purpose for an advantage gain over their competitors

that is not allowed by the rules or otherwise given permission to do, by the track or MWRA officials such as tampering with

any part of the carburetor, head, block, cam, after market cam, wrong rod, wrong piston, wrong head gasket, wrong fuel, arguing

with any MWRA track official or going to track promoters will result in the following:

1st offense: Surrender of illegal parts for destruction.

Loss of all track points for that night and two week suspension (14 days/2 regular races) from all MWRA tracks and events.

No penalty for rain outs.

2nd offense: Immediate suspension for the remainder of the year from all MWRA tracks and events.

M: Any car jumping the start or witnessed rough driving will be disqualified and earn no points for that race. Driver

will receive a warning. Second offense will result in disqualification for 2 weeks. Third offense will result in suspension

for the remainder of the year from all remaining MWRA races and events.

N: Any car refusing inspections will be automatically suspended from specific track that refusal occurred for the remainder

of the season.

|